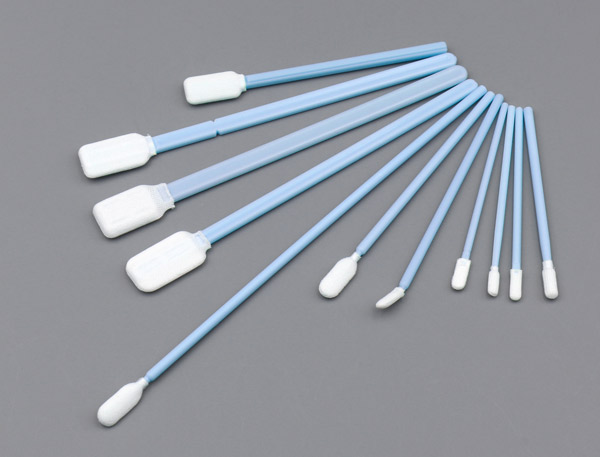

When it comes to precision cleaning and contamination control, choosing the right type of swab is crucial. Microfiber swabs and polyester swabs are both widely used in cleanrooms, electronics, medical, and industrial environments. While they may appear similar, their properties and applications differ significantly. In this post, we’ll explore the key differences between microfiber swabs and polyester swabs to help you make an informed decision.

What Are Microfiber Swabs?

Microfiber swabs are cleaning swabs made from ultra-fine synthetic fibers, typically a blend of polyester and polyamide. The fibers are tightly woven to create a soft, absorbent tip that traps dust, particles, and even bacteria more effectively than many other materials.

Key Features of Microfiber Swabs:

- Extremely soft and non-abrasive

- High absorbency and particle entrapment

- Lint-free and non-shedding

- Ideal for sensitive surfaces

- Excellent chemical resistance

Microfiber swabs are especially useful in optical, medical, and electronics applications where scratch-free cleaning and superior particle capture are required.

At MediTech, we offer a full line of high-performance microfiber swabs designed for professional use. Our top-selling models include: MS707, MS713, MS714, MS761, MS766, MS758, MS759. All microfiber swabs are lint-free, sterile options available, and customizable for OEM/ODM orders.

🔗 Browse our full range of Microfiber Cleaning Swabs

What Are Polyester Swabs?

Polyester swabs have tips made of 100% knitted polyester, known for its strength, cleanliness, and resistance to abrasion. The material is durable and non-linting, making it suitable for critical cleaning in cleanroom environments.

Key Features of Polyester Swabs:

- Durable and abrasion-resistant

- Chemically compatible with most solvents

- Non-shedding and low particulate release

- Often used for applying and removing solutions

- Heat-sealed construction prevents contamination

Polyester swabs are commonly used in pharmaceuticals, aerospace, semiconductors, and medical device manufacturing.

We supply a comprehensive selection of polyester cleaning swabs that meet the highest quality standards for cleanroom and industrial applications: PS707, PS714, PS761, PS766, PS758, PS743, PS768.

🔗 Explore our full range of Polyester Cleaning Swabs

Microfiber vs. Polyester Swabs: Key Differences

| Feature | Microfiber Swabs | Polyester Swabs |

|---|---|---|

| Material | Micro-denier synthetic fibers (polyamide/polyester blend) | Knitted 100% polyester |

| Absorbency | Higher absorbency | Moderate absorbency |

| Particle Capture | Excellent (traps micro-particles and bacteria) | Good, but less effective than microfiber |

| Surface Sensitivity | Very gentle on delicate surfaces | Durable and suitable for rugged use |

| Applications | Optical lenses, sensors, electronics | Cleanrooms, semiconductor tools, pharma |

Which Swab Should You Choose?

The choice between microfiber and polyester swabs depends on your specific cleaning needs:

- Choose microfiber swabs for delicate or high-precision tasks requiring excellent absorbency and ultra-clean performance (e.g., camera sensors, lab equipment, or optics).

- Choose polyester swabs for more robust cleaning tasks that demand durability, solvent resistance, and consistent performance in critical environments (e.g., medical device assembly or cleanroom wiping).

Not sure which swab fits your needs? Our technical team can help you select the best product for your application or even develop custom swabs through our OEM/ODM services.

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech

Cleanroom Foam Swabs, Polyester Swabs, Printer Cleaning Kit Manufacturer – MediTech